Testing and Validation

Testing and Validation in Forging Excellence

At Sachin Forge Engineering Solutions, we recognize that superior forging quality depends on rigorous testing and validation at every stage of production. To deliver world-class Aluminium and other Non-Ferrous Metal Forging components, we have integrated advanced testing and validation facilities directly into our manufacturing process.

At Sachin Forge Engineering Solutions, testing and validation are not just processes—they are the backbone of our promise to deliver world-class forging solutions with uncompromised quality.

Process Control in Forging Excellence

At Sachin Forge Engineering Solutions, we believe that delivering world-class forging products begins with strict process control at every stage of manufacturing. From raw material handling to the final product, our focus is on maintaining the highest quality standards to ensure precision, reliability, and customer satisfaction.

Precision in Every Stage of Forging

To achieve excellence, we rigorously monitor and control key manufacturing parameters. This ensures that every Aluminium and other Non-Ferrous Metal Forging component we produce is consistent, durable, and meets international benchmarks. By applying strict controls, we minimize variations and guarantee uniformity throughout the production process.

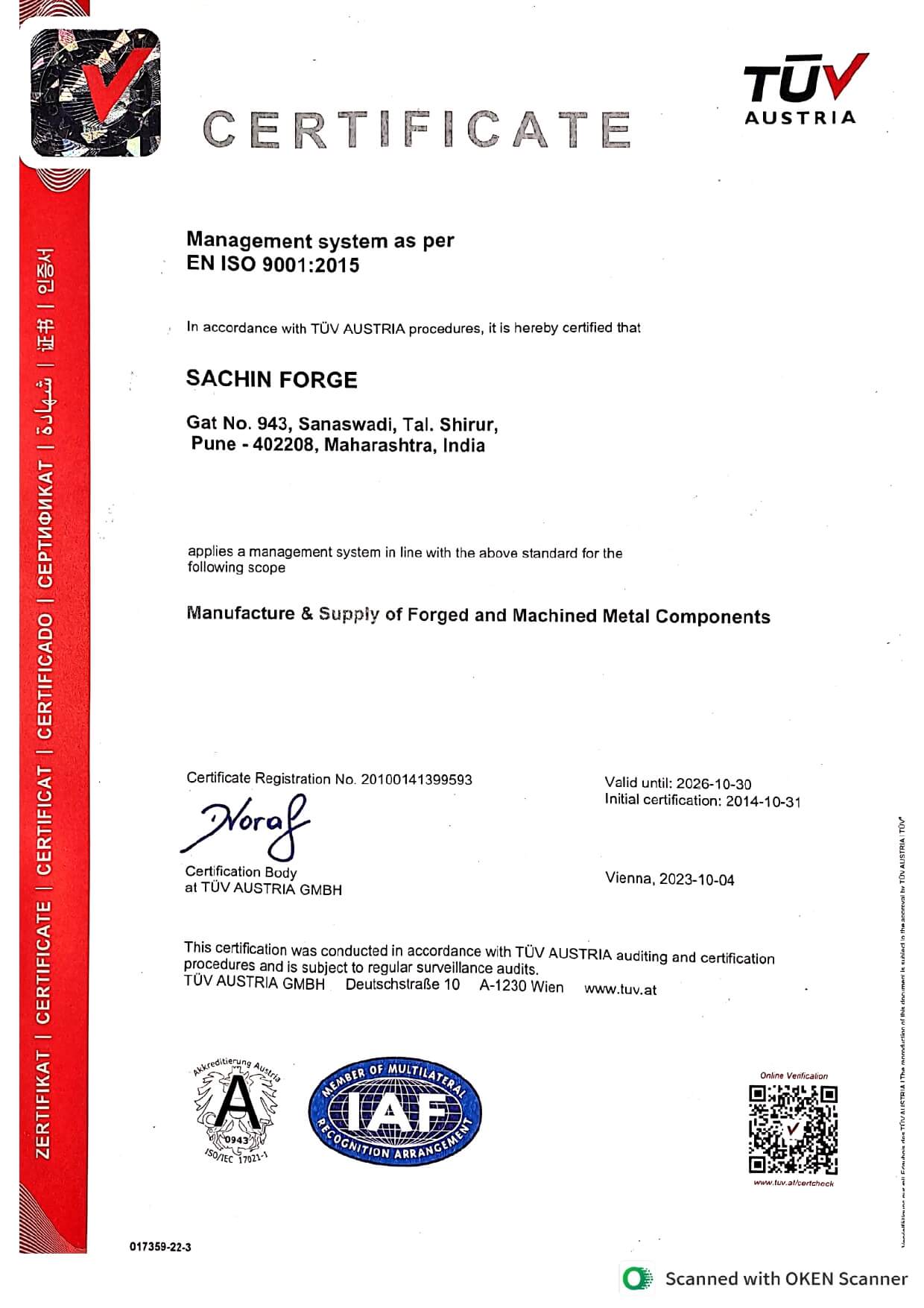

Compliance with Global Standards

Our process control framework is aligned with globally recognized ISO and IATF standards. These standards guide our operations, ensuring that each product is manufactured under the most stringent quality protocols. This commitment enables us to consistently deliver forging solutions that surpass industry expectations.

Continuous Improvement for Forging Excellence

We strongly believe in continuous improvement. By learning from past performance and adopting the latest technological advancements, we constantly refine our processes. This allows us to adapt to challenges, enhance efficiency, and achieve superior quality outcomes in aluminium and other non-ferrous forging solutions.

Our Commitment to Quality

Through meticulous process control and a culture of innovation, we ensure that every forged component is a true representation of our dedication to craftsmanship and excellence. At Sachin Forge Engineering Solutions, our pledge is clear—deliver forging products that not only meet but consistently exceed customer expectations.

At our company, we believe that quality is the foundation of trust.

At our facility, we take pride in adhering to the highest standards of aluminium and other non-ferrous metal forging.

To ensure unmatched quality and customer satisfaction, we operate under globally recognized certifications and approvals that guarantee precision, compliance, and reliability in every component we manufacture.